The guiding framework for our #climatepositive course

We are at the forefront of the energy transition. As pioneers in sustainable energy, we have committed to a strategic course that will make us #climatepositive by 2035. This commitment is underpinned by our focus on driving the heat and electricity transitions and the expansion of renewable energy sources, alongside active waste reduction and repurposing.

"Our new branding is not a superficial change or an attempt to appear more sustainable; it is rooted in our genuine commitment to climate action."

With the rebranding of MVV Environment, we have taken a significant step forward in aligning our identity with our climate ambitions. We did not adopt this new, green branding lightly—it was only after we could substantiate our climate claims through verifiable evidence, that we made this transition. In an industry where greenwashing is unfortunately prevalent, we wanted to ensure that our actions spoke louder than any marketing message.

Climate-friendly energy generation

MVV Environment is one of only three companies worldwide whose targets have been verified as net-zero compatible by the Science Based Targets Initiative (SBTi). Net zero compatible means that, by 2035, MVV Environment will be able to reduce its CO2 emissions along the whole of the value chain to net zero. What counts here is the actual reduction in CO2 emissions at MVV itself and in its supply chain, i.e. at its customers and suppliers. MVV is not relying on offsetting certificates or projects. We believe in real, direct reductions in emissions.

Driving the UK Heat and Electricity Transition

Heating and hot water in residential buildings account for a significant share of global CO2 emissions. Achieving a successful energy transition depends on transforming how heat is generated and supplied.

Our commitment is to develop energy infrastructure that enables sustainable heating systems. This approach is already making an impact at our largest project in the UK so far, the Devonport Energy from Waste (EfW) Combined Heat and Power (CHP) Facility in Plymouth. Since 2015, this modern and efficient facility has been using up to 265,000 tonnes of household, commercial and industrial residual waste per year to generate electricity and heat, notably for His Majesty’s Naval Base Devonport in Plymouth.

Beyond heat, our long-standing investment in renewable electricity generation is central to our strategy. At our biomass power facility at Ridham Dock, Kent, we use up to 195,000 tonnes of waste and non-recyclable wood per year to generate almost 188 million kilowatt-hours of electrical energy. The plant has a net electrical capacity of 23 megawatts.

By 2035, we will fully transition all remaining fossil-based generation to green energy sources.

We are actively repurposing waste and reducing landfill

By 2035, MVV will not only be climate neutral—we will be #climatepositive, removing more harmful greenhouse gases from the atmosphere than we emit. A key pillar of this strategy is waste incineration.

In the UK now, over 15 million tonnes of non-recyclable waste per year still goes to landfill or is shipped abroad for disposal. These landfill sites produce methane, which is 25 times worse than CO2 as a greenhouse gas and exporting waste requires it to be shredded, baled and transported far greater distances than treating it locally. This is not sustainable, and we should be treating this waste as a resource.

"We don’t view these initiatives as just another step in meeting targets—they are about building a greener energy future for the UK."

CO2 is released when non-recyclable waste decomposes naturally or is incinerated. At our waste incineration plants, we can capture this greenhouse gas directly from the flue, securely storing it to prevent the emissions from reaching the atmosphere. We use this energy in the form of heat, electricity and process steam for industrial and residential use. By capturing and securely storing or repurposing the carbon compounds from flue gases before they reach the atmosphere, we can take this process a step further—making it not just carbon neutral, but CO2 negative.

Firstly, non-recyclable waste is significantly reduced in volume. During this process, any contaminants and hazardous substances are fully neutralised.

Then, residual emissions of particulate matter, nitric oxides and sulphur dioxides are filtered out using state-of-the-art flue gas cleaning systems.

At the end of the process, we recover valuable materials—such as metals and resources for the construction industry—for reintegration into the economic cycle and making them usable again.

At our Plymouth Davenport EfW plant, we stop around 200,000 tonnes of residual waste from going to landfill each year, providing an alternative to landfill for local businesses. Beyond waste reduction, we generate valuable energy from non-recyclable materials. As an alternative to landfill, thermal treatment and efficient recovery of energy offers several advantages including environmental and financial benefits. This process not only reduces waste, but allows us to recycle 57,000 tonnes of bottom ash into construction materials annually, along with 7,500 tonnes of metals for recycling.

We will be #climatepositive by 2035

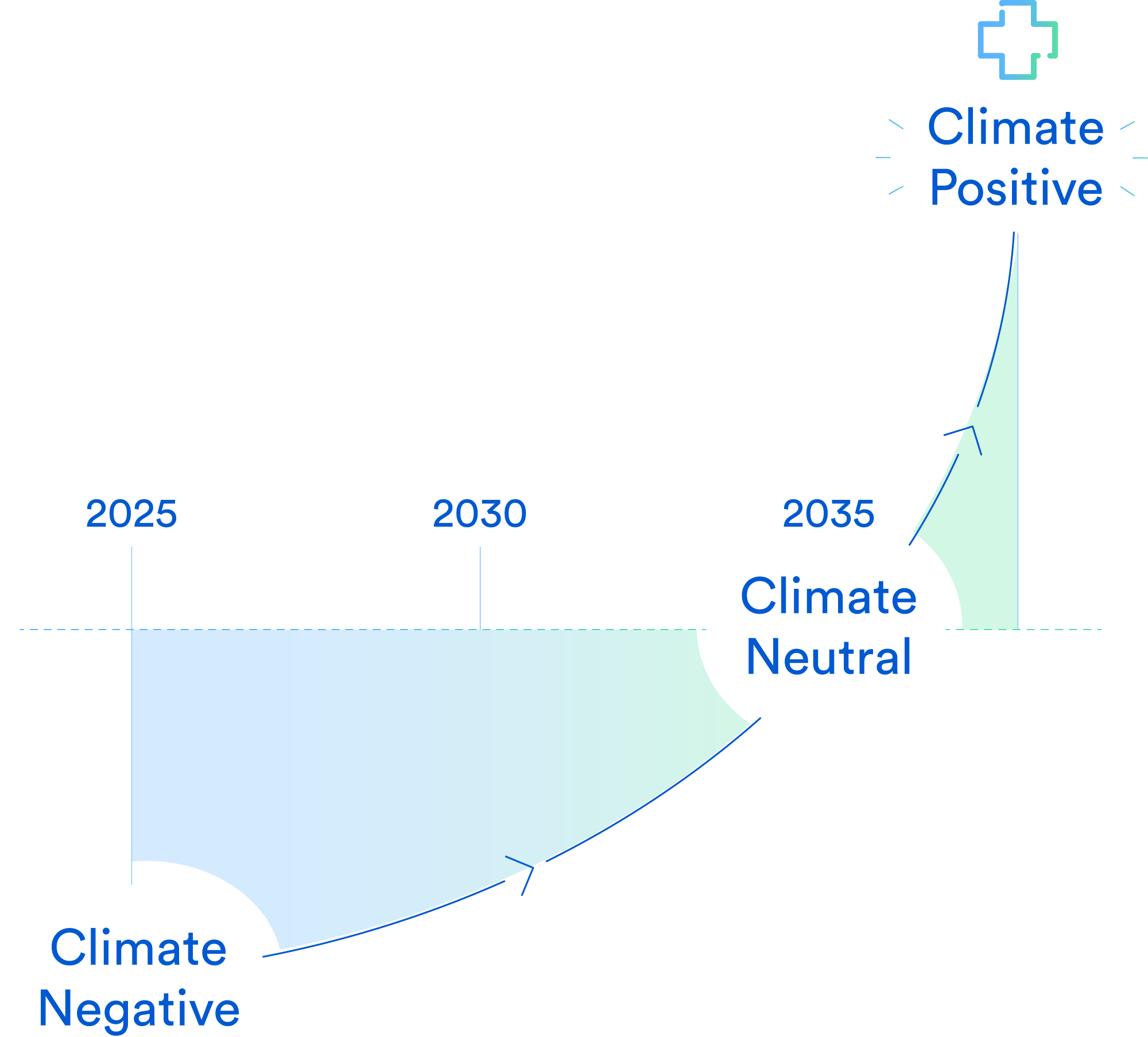

Our journey to #climate positive status includes an interim step: shrinking our total carbon footprint to net zero by 2035. Our climate balance sheet accounts for all greenhouse gas sources, including emissions from upstream and downstream supply chains and our shareholdings.

Additionally, though our work with BECCUS (Bioenergy Carbon Capture Usage and Storage) we will actively withdraw CO2 from the atmosphere, permanently binding, using or storing this gas. As we gain operational experience with this technology, we will gradually extend the use of it throughout our plant portfolio—allowing us to offset our own unavoidable residual emissions. Thanks to the additional CO2 withdrawn from the atmosphere, our overall emissions will turn negative by 2035 already and we will become #climatepositive.

In 2025, MVV have created the first climate-positive facility that actively removes CO2 from the atmosphere.

By 2030, MVV will equip other bio-waste anaerobic digestion and biomethane plants with BECCUS.

By 2035, MVV will exclusively offer 100% climate-neutral products and services with upgrade technology at our plants to permanently remove CO2 from the atmosphere.

At the waste incineration plants, non-recyclable waste is first significantly reduced in volume. During this process, any contaminants and hazardous substances are fully neutralised. We then obtain valuable energy from the waste.